top of page

METHOD OF PROTECTING AN EXPANSION JOINT IN WALL AND FLOOR ACCORDING TO ETA-17/1059

1 - rigid wall with a thickness of B ≥ 150 mm, density ≥ 600 kg/m3 and D = 5 ÷ 60 mm

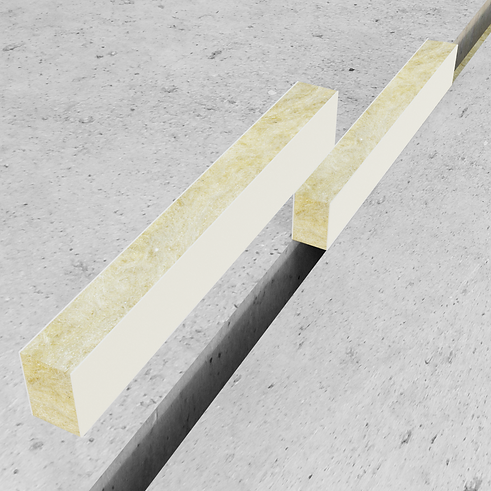

2 - mineral wool with a density of not less than 120 kg/m3

6 - Piro Acrylic Sealant AC120, with a thickness of t2 ≥ 2.5 mm, t3 ≥ 3 mm

Technical drawing 1

1 - rigid floor with a thickness of B ≥ 150 mm, density ≥ 600 kg/m3 and D = 5 ÷ 60 mm

2 - mineral wool with a density of not less than 120 kg/m3

6 - Piro Acrylic Sealant AC120, with a thickness of t2 ≥ 2.5 mm, t3 ≥ 3

Technical drawing 2

Apply Piro Acrylic Sealant

AC120 by using a putty

knife on both sides on the mineral wool board with

a minimum density of 80 kg/m3.

Steps 1 - 5

Place prepared mineral wool

boards inside the expansion

joint at one of its edges.

By using a putty knife apply

Piro Acrylic Sealant AC120O

on mineral wool boards.

Fill the remaining expansion

joint with mineral wool boards

with a density of 80 kg/m3 with

Piro Acrylic Sealant AC120

applied previously, the same

way as in step 1.

Properly protected

expansion joint.

Apply Piro Acrylic Sealant

AC120 by using a putty

knife on both sides on the mineral wool board with

a minimum density of 80 kg/m3.

Steps 1 - 5

Place prepared mineral wool

boards inside the expansion

joint at one of its edges.

By using a putty knife apply

Piro Acrylic Sealant AC120O

on mineral wool boards.

Fill the remaining expansion

joint with mineral wool boards

with a density of 80 kg/m3 with

Piro Acrylic Sealant AC120

applied previously, the same

way as in step 1.

Properly protected

expansion joint.

bottom of page